Truck maintenance is an essential aspect of owning and operating a truck or tractor. Regular preventative maintenance is crucial for the efficient performance of trucks and tractors on the road.

Proper maintenance reduces the risk of breakdowns, which can cause delays in delivery time and inconvenience customers.

This can have a significant impact on small-owned businesses looking to maximize profits.

Consistent maintenance also helps to improve fuel consumption and overall efficiency, which is especially important for those operating on tight budgets.

Trucks are built to withstand harsh conditions on the roads, but they still require regular upkeep to maintain their performance levels.

Failure to perform proper maintenance can result in costly repairs that could have been avoided with consistent care.

Regular checks should be conducted on tires, brakes, fluids, belts, hoses, batteries, and lighting systems.

These checks will help ensure that everything is functioning correctly and reduce the risk of breakdowns while driving down the highways.

Why Regular Truck Maintenance is Crucial

According to research conducted by Fleet Advantage, fleets that replace their trucks every three years can save up to 25% in maintenance costs and 15% in fuel costs.

This is because newer trucks are more fuel-efficient and require less maintenance than older models.

Another study by the American Transportation Research Institute (ATRI) found that the top mechanical issue leading to truck breakdowns was tire-related problems, accounting for 53% of all breakdowns.

According to a survey conducted by FleetNet America (a provider of fleet maintenance and repair services), over 80% of all roadside breakdowns could have been prevented with proper preventive maintenance.

This shows just how important it is for companies to prioritize regular truck maintenance in order to avoid costly downtime due to unexpected repairs.

Prevents Breakdowns

Regular truck maintenance is crucial for many reasons, but one of the most important is that it helps prevent breakdowns.

When a truck breaks down, it can cause delays and lost revenue for companies. Regular maintenance helps identify potential issues before they turn into major problems, preventing breakdowns that could lead to costly repairs and downtime.

For example, if a truck’s brakes are not properly maintained, they may fail while on the road.

This could cause an accident or result in damage to the cargo being transported. By regularly inspecting and maintaining the brakes, potential issues can be identified and addressed before they become a problem.

Increases Safety

Another reason why regular truck maintenance is so important is that it increases safety on the road.

Properly maintained trucks are less likely to experience accidents due to faulty brakes, worn-out tires, or other issues that can compromise safety on the road.

For instance, if a truck’s tires are not properly inflated or have worn treads, they may blow out while driving at high speeds.

This could make you lose control of the vehicle and potentially cause an accident.

By regularly inspecting and maintaining tires, potential issues can be identified and addressed before they become a problem.

Extends Lifespan

Regular maintenance can also help extend the lifespan of a truck by keeping it in good condition, reducing wear and tear on its components, and ensuring that it operates efficiently.

This can save money in the long run by reducing the need for frequent replacements or repairs.

For example, if a truck’s engine oil is not changed regularly or if its air filters are clogged with dirt and debris, this can put extra strain on the engine and reduce fuel efficiency.

Over time this will cause more wear and tear on engine components which will eventually lead to expensive repairs or even the replacement of parts.

When and How Often Should a Truck Be Maintained?

The frequency of maintenance for a truck is crucial to its longevity and performance.

Regular maintenance is the best way to keep a truck running smoothly and prevent costly breakdowns.

However, the frequency of maintenance depends on several factors, including the age of the truck, its mileage, and the type of driving it does.

Trucks should be serviced every 10,000 to 15,000 miles or every six months,

This is a good starting point for most trucks but may not be suitable for all vehicles. For instance, if you use your truck for heavy-duty tasks such as towing or hauling cargo frequently, you may need more frequent maintenance.

The manufacturer’s recommended maintenance schedule for your specific make and model of truck is also an important factor to consider when determining how often your truck needs servicing.

The manufacturer’s recommendations are based on extensive testing and research that takes into account various factors such as engine design and driving conditions.

It’s essential to follow the manufacturer’s recommended schedule to ensure optimal performance and longevity.

Skipping scheduled maintenance can lead to severe problems down the road that could result in costly repairs or even total engine failure.

In addition to following the manufacturer’s recommended schedule, there are some signs you can look out for that indicate your truck needs servicing.

These include unusual noises coming from under the hood or brakes that feel spongy or unresponsive.

Another factor to consider when determining how often your truck needs servicing is its age.

Older trucks generally require more frequent maintenance than newer ones due to wear and tear on various components over time.

Finally, it’s worth noting that regular oil changes are one of the most critical aspects of maintaining a healthy engine.

Oil lubricates moving parts within an engine while also removing harmful contaminants that can cause damage over time.

As such, it’s essential to change your oil regularly according to the manufacturer’s recommendations.

Recommended Maintenance Schedule for Trucks

Preventative maintenance is essential for keeping trucks in good condition and avoiding breakdowns on the road.

Regular maintenance tasks such as oil changes, tire rotations, and brake inspections should be performed according to the manufacturer’s recommended schedule.

Following a preventative maintenance plan can also help extend the lifespan of a truck and save money on costly repairs in the long run.

Oil Changes

Regular oil changes are one of the most important preventative maintenance tasks for any vehicle, including trucks.

The frequency of oil changes depends on several factors such as driving conditions and climate.

However, most manufacturers recommend an oil change every 5,000 to 7,500 miles or six months, whichever comes first.

Neglecting regular oil changes can lead to engine damage and decreased fuel efficiency.

Tire Rotations

Tire rotations are another crucial preventative maintenance task that should not be overlooked. Tire rotations ensure even wear on all four tires by moving them from one position to another.

This helps extend the life of your tires and improve handling and traction while driving.

Manufacturers typically recommend tire rotations every 6,000 to 8,000 miles or six months.

Brake Inspections

Brakes are essential for safe driving; therefore, it is crucial to have them inspected regularly.

Brake inspections include checking brake pads, rotors, calipers, hoses, and lines for wear or damage. Manufacturers usually recommend brake inspections every 12 months or 12k-15k miles.

Other Maintenance Tasks

Apart from these three critical preventive maintenance tasks mentioned above – there are other preventive measures that need attention too:

- Fluid Check & Top-Up: Checking fluids like coolant/antifreeze levels (which prevent overheating), transmission fluid level (which keeps transmission running smoothly) etc., at regular intervals is important.

- Air Filter Change: A dirty air filter reduces engine performance by restricting airflow into the engine; hence it is necessary to replace air filters periodically per manufacturer’s recommendations.

- Battery Maintenance: Checking the battery’s condition and cleaning its terminals regularly can help prevent unexpected breakdowns.

Following the recommended maintenance schedule for trucks is essential to keep them in good condition.

A preventative maintenance plan can help you avoid costly repairs in the long run, extend the life of your truck, and ensure safe driving.

Check Tire Pressure Regularly

One of the most important things you can do to maintain your tires is to check their pressure regularly.

Properly inflated tires not only improve fuel efficiency but also provide better handling and traction on the road.

Running on underinflated or overinflated tires can cause uneven wear, which can lead to premature tire failure.

To check tire pressure, use a tire pressure gauge and compare the reading with the recommended pressure listed in your vehicle manual or on the driver’s side door jamb.

It’s important to note that tire pressure should be checked when the tires are cold, as heat from driving can cause an increase in pressure.

Inspect Tires for Signs of Wear and Tear

In addition to checking tire pressure, it’s also important to inspect your tires for any signs of wear and tear.

Look for cracks, bulges, punctures, or any other damage that could compromise their safety.

If you notice any issues with your tires, have them inspected by a professional mechanic immediately.

Rotate Tires Every 5,000-7,000 Miles

Rotating your tires every 5,000-7,000 miles is another key aspect of proper tire maintenance.

This helps ensure even wear across all four tires and prolongs their lifespan. Front-wheel-drive vehicles tend to wear out front tires faster than rear ones due to weight distribution differences between front and rear axles.

Replace Tires When Tread Depth Reaches 4/32 of an Inch or Less

As a general rule of thumb, it’s time to replace your truck’s tires when the tread depth reaches 4/32 of an inch or less.

This is because tires with shallow tread depth can’t provide proper traction on the road, especially in wet or snowy conditions.

To check the tire tread depth, use a penny and insert it into the grooves of your tire with Lincoln’s head upside down. If you can see the top of Lincoln’s head, it’s time to replace your tires.

Invest in High-Quality Tires

Consider investing in high-quality tires that are designed for heavy-duty trucks and can withstand long hours of running on the road.

While they may be more expensive upfront, they will save you money in the long run by providing better fuel efficiency and lasting longer than cheaper alternatives.

Keep a Spare Tire On Hand

Lastly, always keep a spare tire on hand in case of emergencies.

Make sure it is properly inflated and in good condition so that you can quickly replace a flat tire if needed. It’s also important to know how to change a flat tire safely before hitting the road.

Checking and Changing Fluid Levels in Your Truck

Regularly checking the fluid levels in your truck is an essential part of maintaining its longevity.

The fluids in your vehicle are responsible for keeping all the important parts lubricated, cool, and functioning correctly.

Without proper fluid levels, your truck can suffer from damage that may be costly to repair.

Other Important Fluids

In addition to checking your oil regularly, there are other fluids that require attention as well:

- Coolant: Coolant helps regulate temperature in both hot and cold weather conditions by circulating through various parts of your truck’s cooling system. Low coolant levels can lead to overheating or freezing up of some components of this system.

To check coolant levels, locate either a translucent overflow tank or radiator cap (when cool) underhood; if low top off with 50/50 mix of antifreeze and water.

- Brake Fluid: Brake fluid is responsible for transmitting force from the brake pedal to the brake pads, which stop your truck. Low levels of brake fluid can cause decreased stopping power or even complete failure of your brakes.

To check your brake fluid level, locate the reservoir under the hood with a “max” and “min” line on it. If it’s below the “min” line or looks dirty, you’ll need to add more or replace it entirely.

- Power Steering Fluid: Power steering fluid helps make steering easier by reducing friction between moving parts in the steering system. Low levels of power steering fluid can cause difficulty turning your wheels.

To check your power steering fluid level, locate the reservoir under the hood with a dipstick attached to its cap. If it’s below optimal levels, add more until you reach recommended levels.

- Transmission Fluid: Transmission fluid lubricates all moving parts inside an automatic transmission and keeps them cool. Low transmission fluid levels can lead to overheating and damage to this important component of your truck.

To check your transmission fluid level, park on a flat surface with the engine running at operating temperature (check owner manual) while shifting through gears before checking dipstick; if low add as needed according to manufacturer recommendations.

Changing Your Fluids

If any of these fluids are low or dirty, it’s essential to change them as soon as possible.

Follow manufacturer recommendations for how often each type of fluid should be changed based on mileage or time intervals (whichever comes first).

It’s always best to consult your owner’s manual for specific instructions regarding changing fluids in your truck.

However, some general guidelines include:

- Changing oil every 3-5k miles

- Flushing coolant every 2 years

- Replacing brake fluid every 2 years

- Flushing power steering system every 75k miles

- Changing transmission oil every 30k miles

By following these guidelines and regularly checking your fluid levels, you can help ensure that your truck runs smoothly and efficiently for years to come.

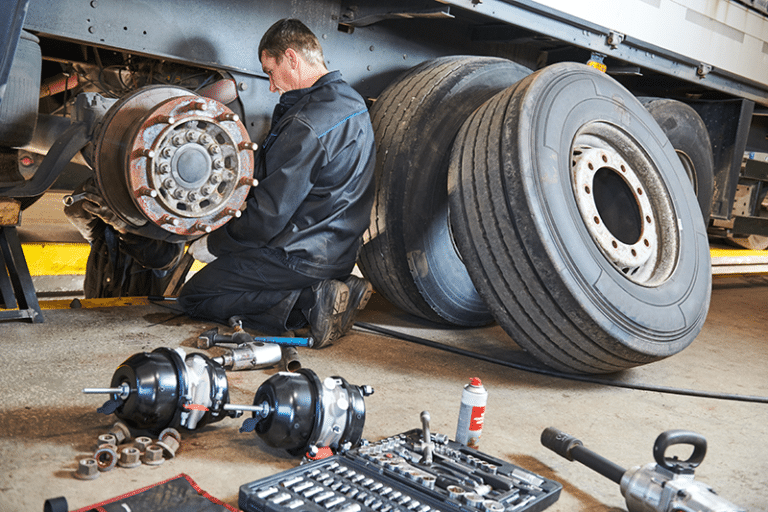

Inspecting Brake Pads and Rotors

Brake pads and rotors are two essential components of a vehicle’s braking system. Over time, these parts wear out due to friction generated during braking.

Regular inspection of brake pads and rotors can help detect any signs of wear and tear before they become severe issues.

To inspect brake pads, remove the wheel to gain access to the brake caliper. Inspect the thickness of the pad; if it has worn down to less than 1/4 inch, it’s time to replace them. Additionally, check for any uneven wear or cracks on the surface.

Rotors should also be inspected regularly for signs of wear such as grooves or scoring on their surface. If there are visible grooves or scoring on the rotor surface, it may need resurfacing or replacement.

Perform Routine Maintenance On The Brake Mechanism

Routine maintenance on the brake mechanism is essential for its longevity and optimal performance. Cleaning and lubricating with appropriate grease prevents corrosion and rust from forming.

Before applying grease, clean all parts thoroughly with a suitable cleaner like brake cleaner spray or rubbing alcohol.

Then apply an appropriate amount of grease using a brush or your fingers while making sure not to overdo it.

Keep a Checklist

Keeping a checklist is an excellent way to stay organized when performing regular maintenance checks on your vehicle’s brakes.

It helps ensure that all necessary steps are taken by following recommended maintenance tasks like replacing brake fluid or inspecting brake lines.

Address Any Brake Issues Immediately

It’s crucial to address any issues related to brakes immediately because they can lead to potential safety hazards down the line if left unattended.

Delaying repairs can also result in more significant and costly repairs.

If you notice any unusual noises, vibrations, or difficulty when applying the brakes, it’s time to have them inspected by a professional. It’s better to be safe than sorry when it comes to brake issues.

Don’t Neglect Your Truck

In addition to these specific components, it’s important to keep up with general maintenance tasks such as checking fluid levels regularly and replacing worn-out parts promptly.

By following a recommended maintenance schedule for your truck, you can help prevent breakdowns on long routes.

Regular truck maintenance isn’t just about keeping your vehicle running smoothly – it’s also about ensuring safety on the road for yourself and others around you.

A well-maintained truck will have fewer breakdowns which means less downtime on routes giving more time with family at home. Read more trucking tips at Canal Cartage.